Oct 11,2025

As Europe accelerates its transition toward compact, clean, and license-free mobility, L6e-BP micro EVs, also known as electric quadricycles, are becoming an increasingly important segment of the urban mobility market. Behind their growing adoption lies a fundamental technical factor that directly influences safety, regulatory compliance, and long-term commercial viability: structural engineering.

For distributors, importers, and dealers evaluating L6e-BP micro EV suppliers, the choice between unibody structures and plastic frame structures is not merely a design preference. It is a strategic decision that affects vehicle behavior in daily operation, EU type-approval robustness, insurance acceptance, repairability, and total cost of ownership.

This article explains why, in the L6e-BP segment, structural engineering matters, and how unibody and plastic frame structures differ in practical, regulatory, and commercial terms.

Although L6e-BP micro EVs are limited to a maximum speed of 45 km/h, they operate in real traffic environments and carry passengers on public roads. Consequently, EU technical services and insurers place clear emphasis on structural performance, not only on powertrain or electronic systems.

Key structural aspects assessed during approval and insurance evaluation include:

Load-bearing capacity and torsional rigidity

Defined frontal and side impact energy paths

Battery enclosure protection against intrusion

Seat-belt anchorage strength

Suspension mounting consistency

Structural behavior under emergency braking and cornering

In real-world use, the vehicle structure has a greater impact on safety margins, driving stability, NVH performance, and long-term durability than battery size or motor output. For dealers, this directly translates into warranty exposure, customer satisfaction, and brand credibility.

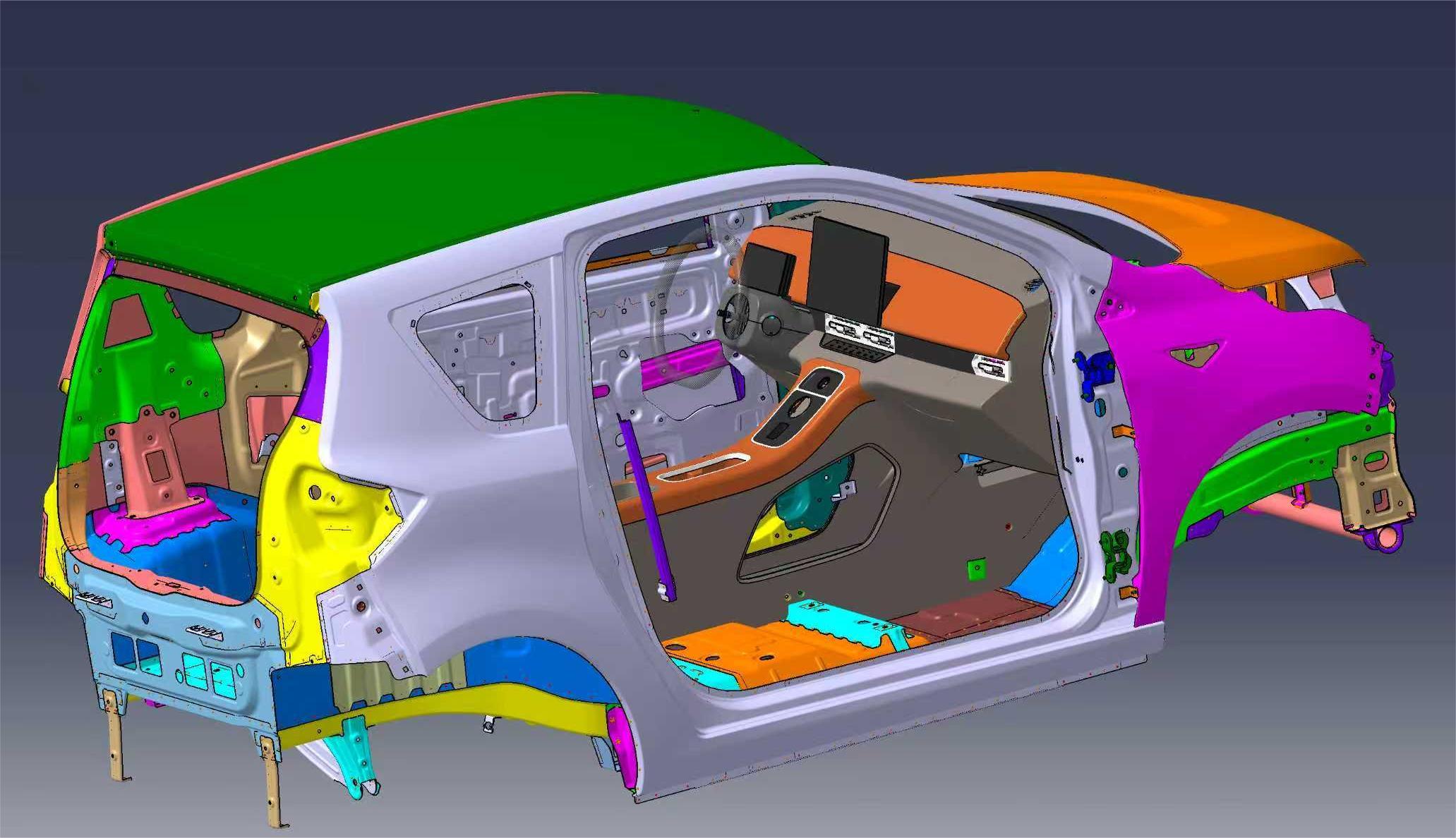

A unibody (monocoque) structure integrates all primary load paths into a single, continuous metal body. The body itself functions as the main load-bearing element and typically includes:

A load-bearing occupant safety cell

A structurally integrated battery enclosure

Front and side structures designed to manage crash energy

Direct mounting points for seats, seat belts, and suspension

Predictable and repeatable crash deformation behavior

High torsional rigidity

Structural battery protection

Stable suspension geometry over the vehicle's service life

Automotive-grade structural integration

Lower long-term warranty risk

Strong insurance acceptance

Higher consumer confidence

More stable residual values

Proven durability in fleet and shared-mobility use

While plastic frame structures dominate the current L6e-BP market, unibody construction remains the reference architecture for passenger vehicles where long-term structural stability is a priority.

A plastic frame structure typically combines:

A metal frame or sub-structure carrying the primary loads

Plastic exterior panels and modules

A non-load-bearing cabin enclosure

In this architecture, plastic components are used mainly for enclosure, styling, and weather protection. Structural performance depends largely on the design quality and stiffness of the underlying metal frame, as well as the durability of interfaces between frame and body modules.

Overall rigidity is frame-dependent

Crash behavior varies across designs

Battery protection relies on frame geometry and reinforcements

Load transfer occurs through multiple joints and interfaces

Long-term alignment and NVH depend on connection durability

Greater variability in real-world vehicle behavior

Perceived quality differences between markets

After-sales performance closely tied to frame robustness

Plastic frame structures are the mainstream solution in today's L6e-BP micro EV segment, largely due to manufacturing efficiency and cost control, provided that the metal frame meets regulatory expectations.

Unibody vs. Plastic Frame Structures

Rigidity: High vs Frame-dependent

Crash behavior: Predictable vs Design-dependent

Battery protection: Structurally integrated vs Frame-reliant

Driving stability: Consistent vs Variable

Long-term alignment: Stable vs May change over time

NVH performance: Generally lower vs Connection-dependent

Repairability: Clear structural reference vs Interface-complex

Driving Stability

Unibody structures provide more consistent steering and braking behavior. Plastic frame structures may exhibit greater variation depending on frame stiffness and joint design.

Urban Durability

Unibody platforms generally tolerate repeated stop-start traffic, uneven road surfaces, and long-term vibration more consistently.

Crash Safety

Unibody designs integrate deformation zones into the body structure, while plastic frame vehicles rely primarily on the metal frame to manage impact loads.

Fleet Applications

For shared mobility, rental, and logistics fleets, unibody structures are often preferred due to predictable durability and reduced downtime risk.

Reduced warranty and after-sales costs

More consistent insurance acceptance

Stronger positioning in EU markets

Higher customer satisfaction

Lower total cost of ownership

Predictable long-term vehicle performance

Unibody Structures Are Better Suited For:

Long-term brand development

Quality- and safety-oriented positioning

Fleet and shared-mobility applications

Risk-controlled dealer portfolios

Plastic Frame Structures Are Typically Chosen For:

Lower upfront vehicle cost

Entry-level market positioning

Cost-sensitive regions

Low-utilization or short-cycle applications

In the L6e-BP micro EV segment, structural engineering is the foundation of safety, durability, regulatory compliance, and commercial success. Unibody structures offer higher rigidity, more predictable crash behavior, and lower long-term dealer risk.

While plastic frame structures remain the dominant solution in today’s market, distributors and dealers aiming to establish a stable, credible presence in Europe’s growing micro EV sector should evaluate vehicle structure as a strategic priority, not a secondary specification.